Executive Summary

The new bridge called The Governor Mario M. Cuomo Bridge is a 3.1-mile twin-span bridge. The cost of this bridge was 3.98 billion dollars. The new bridge has four lanes and a dedicated bus lane in each span. This paper would focus on project management on the engineering and coordination part of the super crane and the advances of using this crane in scheduling, safety, and environment.

INTRODUCTION

The Governor Malcolm Wilson Tappan Zee Bridge was a cantilever bridge built from 1952 to 1955 and replaced on 2017. The bridge crossed the Hudson River and connected South Nyack in Rockland County with Tarrytown in Westchester County, N.Y. The bridge was designed with a lifespan of 50 years. Bridge traffic grew to about 140,000 vehicles, far more than the design load of the bridge. Heavy traffic and narrow lanes contributed to be one of the highest accident per mile compared to other Thruways, due to the bridge not having a dedicated emergency lane added to these numbers. In short, the bridge was overburdened and deteriorating. The collapse of Minessota’s I-25W Mississippi River bridge in 2007 put this bridge on consideration for replacement.

The new bridge called The Governor Mario M. Cuomo Bridge is a 3.1-mile twin-span bridge. The cost of this bridge was 3.98 billion dollars. The new bridge has four lanes and a dedicated bus lane in each span. The primary purpose of this paper was to focus on the scheduling of the project, but the publicly available information is not very useful due to the critical information is grayed out. Therefore, this paper would focus on project management on the engineering and coordination part of the super crane and the advances of using this crane in scheduling, safety, and environment.

The project was awarded to TZ constructors, who are a coalition of specialized companies. They were formed specifically for this p roject to address the Governor’s goals of deliveringa project that will create jobs for New Yorkers, stimulate the economy and provide and infrastructure needed for the future growth of the state.

roject to address the Governor’s goals of deliveringa project that will create jobs for New Yorkers, stimulate the economy and provide and infrastructure needed for the future growth of the state.

I believe that a project of this scale you can’t have a single project manager, but a team of project managers. Each of them will take a few areas of project management. Examples of these areas are Design/Engineering, Regulations, Environmental, Cranes, Construction, Protection of Facilities, Demolition, Corrosion, Geotechnics, Workforce, Coordination, Scheduling, Risk Analysis, etc.

One of the most amazing parts of this project was the construction of a crane to load pre-fabricated sections of the bridge and to dismantle the old bridge. The need for this crane was brought to the owners to be used as an essential part of the construction. This vessel, named “I Lift NY” super crane. The crane eliminated the use of multiple cranes, and it removes overloading in stress to the new sections of the bridge by using these cranes on finished parts of the bridge. Also, larger sections of the bridge could be pre-fabricated and installed with this super crane. Having sections of the bridge being pre-fabricated saves time, money, and is safer for the workers.

The most crucial part of scheduling for this project was centered on the construction and availability of the super crane. Without it, the development of the bridge would have been significantly

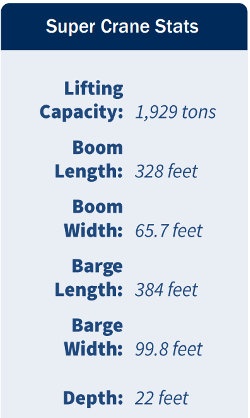

delayed. The installation of piles, removal of the old bridge, lift heavy objects in place while the crew secures it into place. With the lifting capacity of 1,929 tons and adding an extra 10% safety factor, the crane can lift 3,472,200 lbs of weight as I said an additional 10% because, as an engineer, you add a considerable amount of safety before you give your number to the user. Using this crane saves a few months of installation time, and it saves a lot of money. Just on payroll alone, you are saving millions of dollars by reducing months into the project. Also, you have less soil disturbance, less preparation of the area, fewer permits for heavy loads on roadways since now the materials can be transported by water, not to mention fewer environmental impacts as well.

In regards to the environment, the Hudson River was drenched due to multiple reasons; provide space for the foundations of the bridge and to make space for the crane to pass and arrive at the location. The barge is twenty-two feet deep, and it needs buoyancy force to work correctly and not destroy the river bed or the barge itself. This crane could have been used by falcons native to the area to land on them, and particular precaution was used and designed for it not to harm the falcons. Another prevention that had to be managed was marine life. While installing piles, the team created a distinctive noise in the water to alert the marine life and allow time for them to be out of the area. Multiple noise monitoring was installed to guard the nature and environment. Specific thresholds were put in place to safeguard these standards. The team managed various stages to protect the environment and fauna that lives around the construction site. All these elements had to be managed and worked comprehensively and cohesively.

The project management team had to be engaged since the beginning of the construction of this barge/super crane. This crane signifies the success of this project. I understand that in the risk register, it was noted the possibility of this barge not to be able to be used due to river beds of the areas where the barge needs to navigate. I firmly believe that the management of this group of individuals was spectacular. They have achieved saving time on a governmental project and although I was speculative about the amount of time saved in this project, I believe that the use of this crane was the key to success for the entire project.

Of course, not everything in this project runs as smoothly as desired. Some of the non-desired items made the news in NY Times. An example of this unfavorable news is when trying to open the second span of the bridge; it was delayed due to safety concerns. The old bridge was being disassembled. A loud pop around 5 pm on Friday the day before the opening brought New York State Thruway Authority and Tapan Zee Constructors to a halt. TZC was not going to take any risk in opening the new span until they can verify and confirm that the old bridge that is only 160 feet away from the new one was stabilized. There were problems with the joints of the old bridge and they said that the contractors worked hard to get the eastbound span done and that it was sitting empty waiting for traffic was somewhat an embarrassment for them. After multiple engineers from both parts confirmed that the bridge was secured, the new span did not open for traffic.

Conclusion

This construction was a challenging one; a coalition of companies had to be built. Numerous risk factors are taken into consideration. Many phases with many challenges per phase. It dealt with innovations, new bridge design engineering, new technologies, and new super crane. This project represented multiple challenges in all phases, but a significant recognition must be awarded to the project management team. This team was responsible for the coordination, vision, and scheduling of this complex construction. If excellent communication were not established and agreed among so many contributors, this paper would have been on the failure of the Governor Mario Cuomo Bridge. Probably it would not be named that way after all. This project is an example to follow in the professional industry and one that must be studied further to understand and learn more than this brief summary.

Biography:

Omar Sánchez Shumate is an engineer for Consolidated Edison of NY and an MBA student from Montclair State University concentrating in Project Management. Learn more about the author here: https://www.linkedin.com/in/omar-s%C3%A1nchez-607b963/

References:

Most of the information from this article was retrieved from full reports found in:

Home. (n.d.). Retrieved from https://www.newnybridge.com/

Additional references:

1) Tappan Zee Bridge (1955–2017). (2020, February 21). Retrieved from https://en.wikipedia.org/wiki/Tappan_Zee_Bridge_(1955–2017)

2) Tappan Zee Bridge (2017–present). (2020, February 21). Retrieved from https://en.wikipedia.org/wiki/Tappan_Zee_Bridge_(2017–present)

3) Governor Cuomo Announces Opening of First Span of the Governor Mario M. Cuomo Bridge. (2017, August 25). Retrieved from https://www.governor.ny.gov/news/governor-cuomo-announces-opening-first-span-governor-mario-m-cuomo-bridge

4) Korman, R. (2018, June 11). New York Bridge Project Mystery: Cost and Schedule. Retrieved from https://www.enr.com/articles/44581-new-york-bridge-project-mystery-cost-and-schedule

5) Franklin, S. (2018, October 9). Governor Andrew Cuomo accused of dangerously rushing a major bridge opening. Retrieved from https://archpaper.com/2018/09/mario-m-cuomo-bridge-controversy/

6) Goldmacher, S. (2018, December 14). Attorney General Investigating Broken Bolts on Mario Cuomo Bridge. Retrieved from https://www.nytimes.com/2018/12/14/nyregion/mario-cuomo-bridge-broken-bolts-investigation.html

7) Zaveri, M. (2018, September 8). ‘Potentially Dangerous Situation’ on Tappan Zee Delays Opening of New Cuomo Bridge Span. Retrieved from https://www.nytimes.com/2018/09/08/nyregion/old-tappan-zee-bridge-collapse.html

Recent Comments